Sandvik delivered a fleet of mobile crushing and screening equipment for a major construction redevelopment in Hong Kong. The project, which is to take place in five stages and will be the largest of its type ever built in the city, involves the relocation of a sewage treatment works to underground caverns to create a more sustainable and environment-friendly alternative.

Commissioned in 1982, the Sha Tin Sewage Treatment Works (STSTW) was implemented to provide sewage treatment facilities to a population of 226,000 in Sha Tin and Ma On Shan. Progressively expanding, this now serves about 630,000 people and is the largest secondary sewage treatment works in Hong Kong.

To support Hong Kong’s sustainable development, the government decided to actively explore ways of developing new land resources and one option is through the creation of underground caverns. Following a feasibility study on the relocation of the treatment works to caverns, the results confirmed that this was technically and financially viable. Subsequently, investigation and design works for the relocation project commenced in September 2014.

The future cavern complex for the relocated works will be the largest of its type ever built in Hong Kong. The relocation will greatly improve the environment of the existing STSTW site and its surroundings, and release about 28 ha of land for other beneficial uses.

It will be constructed in stages, starting with site preparation and access tunnel construction; construction of the main caverns; installation of the sewage treatment facilities; and finally, decommissioning and demolition of the existing STSTW. Completion of the whole project is expected by 2031.

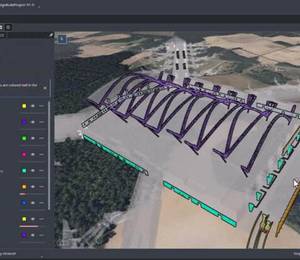

Mobile crushing and screening train

The first stage began in February 2019 and was targeted for completion towards the end of 2022. Discussions relating to the equipment required for the second phase – for which the mobile crushing and screening train was required – were initiated two years prior. Sandvik’s local sales team was already in contact with the customer, Sheung Ying Construction Limited, for drilling and blasting applications. The initial tender was to process the extracted material ROM (run of mine) from the cavern construction. This material was then to be used in different construction projects throughout Hong Kong.

Sandvik’s sales team in Hong Kong led the discussions with the customer and succeeded in closing the deal. Mobile equipment was needed rather than stationary, due to the need to move the machinery on site. The models were selected due to the capacity and sizes required by Sheung Ying Construction Limited.

First in the line-up is a primary jaw crusher, a UJ440i to reduce the granite down to a manageable feed size which is then fed into a US440i secondary cone crusher. Running the ‘S’ cone after the jaw, enables the jaw to be opened up wider to maintain the high capacity required by the customer.

The UJ440i has a large jaw size of 1,200 x 830 mm, which offers great size reduction and consistent performance. Production is maximised through the generous feed opening coupled with a hydraulic close side setting (CSS) that enables rapid changes through push button operation. The jaw also comes complete with a level sensor as standard to maintain optimum material flow in the chamber when crushing. On this particular application, the jaw crusher is fitted with a vibrating grizzly feeder and under-screen for efficient processing.

The US440i secondary cone crusher is capable of accepting large feed sizes of up to 500 mm and, similar to the UJ440i, is ideal for heavy-duty applications. With the use of onboard high-level intelligence together with ASRi (Automatic Setting Regulation), which comes as standard, the systems ensure that the plant is running at the highest capacity, whilst minimising downtime by flagging maintenance issues at the earliest opportunity.

Versatile equipment

From the US440i, the feed is then transferred into a QE442 scalper. The QE442 takes the first cut of the 20 mm fraction size and feeds the +40 mm oversize into the QH441 cone crusher, whilst also screening the sub-base material 20-40 mm as a sub-product. Like the US440i, the QH441 is fitted with the versatile Sandvik Hydrocone crusher. This offers a wide choice of chambers and different settings to allow the machine to be tailored to the specific requirements of the application.

Finally, for screening into the desired fractions of 0-5 mm, 5-10 mm, 10-20 mm and 20-28.6 mm, the QH441 feeds into a QA451 Doublescreen. This QA451 features two high-velocity independently adjustable screen boxes which can be fine-tuned to optimise screening accuracy, efficiency and performance.

The project has been progressing well and is running ahead of schedule. Satisfied with the performance of the Sandvik equipment and needing to increase capacity, China State – Alchmex Joint Venture, the main contractor working on behalf of Sheun Ying Construction Limited, has placed a repeat order of equipment.

The customer’s new line-up will include the same models as the first but with the addition of the new QA452 Doublescreen as opposed to the QA451. This latest development has been designed to provide higher uptime due to easier access for maintenance, quicker set-up and ease of operation, combined with a lower cost of ownership. The QA452 also offers a more sustainable solution with lower emissions, reduced fuel consumption, extended service intervals, optimised hydraulics and less operating noise.