Since 1961, PT Hutama Karya (Persero) has been building Indonesian infrastructure, ranging from high-rise buildings and power plants to roads and airports. Most recently, the company was given a government mandate to build and operate the Trans Sumatra Toll Road, spanning 2,836 km across Sumatra Island, set to be one of the longest toll roads in Southeast Asia. As of May 2021, 663 km of the expressway have been completed and operational. The entire route is expected to be finished by 2024, serving as a new economic corridor for Indonesia’s second-most populous island and contributing 21% of the nation’s gross domestic product.

As part of this US$37.5 billion megaproject, PT Hutama Karya is constructing a 28-km roadway section between Serbelawan district and the city of Pematangsiantar. Consisting of two interchanges and 17 bridges, this section will improve access to the international seaport of Kuala Tanjung and the Lake Toba tourist destination, shortening travel times by 50% and accelerating economic growth and tourism.

“The current road took seven and a half hours [to travel]. But after this section is constructed, it will only take four to five hours of transport from the capital city to the Toba area,” said Amy Widyastuti, BIM manager at PT Hutama Karya. Connecting strategic industries – such as petroleum and coal, and coffee and rubber plantations – with the seaport, the completed roadway network is projected to reduce distribution logistics costs by 30%, which is crucial for boosting the economy.

Seeking digital interoperability

Located in a remote and dense forest area with soft soil, the project initially presented difficult topography and data acquisition challenges, requiring innovative survey structural support methods. Compounding these issues, PT Hutama Karya needed to ensure that its roadway alignment integrated with the existing busy ring road, allowing enough clearance for the underpass. With a multidiscipline team involving 150 contractors using multiple software interfaces and working remotely during Covid-19, PT Hutama Karya also faced significant collaboration and compatibility challenges. Having a lot of issues to solve in a short period of time, the company realised that it needed to implement digital technology from the onset.

Committed to digital design and construction methodologies, PT Hutama Karya applied BIM using various software applications but found that these platforms lacked the capability to capture and handle the voluminous amount of data. “Our team has experienced using other BIM platforms to model this project [and] the coordination between software platforms left several compatibility issues,” said Ms Widyastuti. Seeking to streamline data collection and workflows, PT Hutama Karya needed interoperable digital modelling technology capable of accommodating large data files to improve project collaboration.

An integrated technology solution

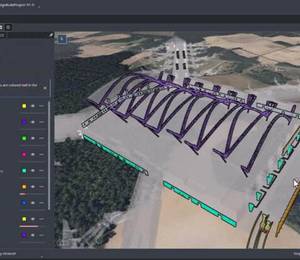

PT Hutama Karya began with a digital survey using unmanned aerial vehicles and LiDAR scanning to capture orthophotos and point clouds amid the remote forested project site, and selected Bentley’s ContextCapture to process them into an accurate reality mesh of the existing field situation. Integrating Bentley’s OpenRoads and OpenBridge for collaborative 3D design, PT Hutama Karya established a BIM model to perform coordinated design reviews. Working in a connected data environment streamlined design among the dispersed team and stakeholders.

From the BIM and reality models, PT Hutama Karya used Bentley’s LumenRT to generate an animated visualisation, simulating construction to digitally determine the impact of the design on the already operating toll roads. The digital visualisation enabled the engineers to determine that there was insufficient clearance between the underpass and ring road, allowing them to redesign the crossing to provide safe clearance.

To address the soft soil issues impacting the structural foundation, PT Hutama Karya performed soft soil and slope stability analyses using Bentley’s Plaxis 2D, which determined that the team needed additional soil treatment and support structures to safely withstand displacement. “We found out there were points of soft soil with a depth of up to 13 m,” said Ms Widyastuti. Based on these findings, PT Hutama Karya decided to add a geotextile layer and installed anchors to resolve the geotechnical engineering issues.

Ultimately, Bentley’s integrated technology solution facilitated coordinated design and a visual digital comparison of the existing site conditions with the built environment, ensuring project viability. “We are able to visualise the comparison of the existing situation, which was a dense forest, with the future constructed environment to ensure the project owner that we can meet their expectation,” said Ms Widyastuti.

High productivity and cost savings

Through digital survey and reality modelling, coordinated engineering design, and collaborative BIM modelling and analysis, PT Hutama Karya reduced the time and costs needed while improving the quality of the project. Using ContextCapture saved 92 days in survey time, measuring and collecting data four times faster compared to traditional methods. “In the 28-km length of this road section, we can provide accurate existing data to be translated into a reality model in 28 days, compared to 120 days using conventional survey methods,” said Ms Widyastuti.

Working in a connected data environment using OpenRoads and OpenBridge for 3D modelling and analysis, PT Hutama Karya streamlined data and workflows, shortening coordination and approval time by up to 34 days. The digital solution not only saved time, but also enabled the team to directly extract material quantities from the model, ensuring accurate cost estimates for the project owner.

Integrating Plaxis for geotechnical analysis helped avoid potential critical failure due to soft soil conditions, avoiding rework during construction and possible maintenance during roadway operations, estimated to save US$1 million. Performing construction simulation with LumenRT allowed engineers to identify and rectify the potential clash with the existing busy ring road prior to on-site works, saving an additional US$1.18 million. Bentley’s integrated technology solution resolved compatibility issues, provided data continuity, and optimised collaboration to save a total of US$2.18 million in costs. The collaborative digital platform provides a single source of data that PT Hutama Karya plans to use throughout construction, operations, and maintenance.

As part of the company’s digital transformation roadmap, the 3D BIM model will serve as the foundation for a lifecycle digital twin, bringing valuable advantages during construction and to the future of the entire Trans Sumatra Toll Road. “The near future goal for PT Hutama Karya is to integrate BIM and GIS as the foundation to build a digital twin to support the company’s objective on digital construction,” said Ms Widyastuti.

All images: PT Hutama Karya (Persero)