Hamm has introduced its HC series – a new generation of earthwork rollers – for the global market. The machines can achieve a high level of compaction power as well as a reduction in CO2 emissions at the same time, according to the manufacturer. All models are also ‘digital-ready’ since they can be equipped with various interfaces for the digital construction site.

With the HC series, Hamm is bringing together two of its previous compactor series – the 3000 series (Tier 3) and the H series (EPA Tier 4/EU Stage V) – on one platform, including models with an operating weights of 11–25 t. The diesel engines comply with the regional requirements, and their power varies between 85 and 160 kW, depending on the weight.

The drum width for all models is 2,140 mm. Apart from the previously known sales variants, Hamm revealed that in future, there will be CR machines with reinforced components for applications on difficult terrain and special equipment for applications on rocky ground.

The HC series is characterised by its new, athletic design and the view channel in the engine hood. A new frame concept also guarantees increased tank volume; in future, the heavy compactors will be delivered to the construction site with a 336-l fuel tank, said Hamm.

Enhanced compaction parameters

In comparison to the predecessor models, Hamm has increased the compaction power for the HC series. The centrifugal force has been increased by up to 15%, while the static linear load is as high as 80.6 kg/cm.

There are new features when it comes to the steering. A new cast articulated joint with articulated joint lock allows for a better steering and swing angle with improved kinematics. Thanks to the optimised weight distribution in combination with the traction control, the gradeability has been further improved.

In addition, the front vehicle and the scraper have been redesigned. This has resulted in significantly increased clearance on the drum, meaning that no material can accumulate there, which eliminates cleaning work.

The integrated Eco mode supports the operator so that they can work in the economical partial-load range as often as possible, thus reducing the need for cooling. The speed is reduced for this, but without compromising the power, thanks to a large travel pump. This concept saves fuel and minimises the noise and exhaust gas emissions. Hamm added that with the optional engine stop system, the energy consumption can be reduced even further.

Comfortable workstation

For greater comfort, the cab offers the operator over 20% more tread, around 30% increased space, and numerous storage compartments. The vibrations and noise level in the cab have also been minimised, owing to the materials and design.

A comfortable heating and air-conditioning system, the Easy Drive operating concept, the innovative seat operating unit, the comfortable steering as well as modern ventilation round off the comfort offered by well-conceived construction machinery.

In the dark, the standard LED lights light up the environment in all working situations. At day and night, thanks to the view channel in the hood, the roller meets the requirements for the field of vision in accordance with DIN EN 474.

On the cab, a large additional mirror with proximity detection enhances the view of the immediate environment, and design tricks guarantee low-vibration mirrors. The mirrors can be easily adjusted from the cab.

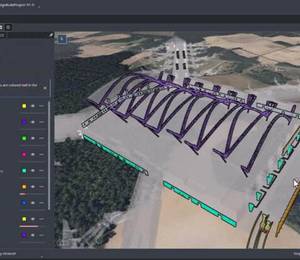

Hamm further highlighted that the HC series is well prepared to meet the needs of future jobsites. The ‘Smart Doc’ app, which was developed by the manufacturer, graphically displays all of the key compaction parameters as well as the compaction progress, and logs the measured rigidity as well as the position data.

In the Smart Doc app, even inexperienced drivers can immediately see which areas have been sufficiently compacted and which areas still require compaction. What’s more, the compactors can communicate, even with digital applications from third parties, via a standardised interface.

Note: The new HC series rollers will be showcased at bauma 2022.

Bauma booth: FS.1011