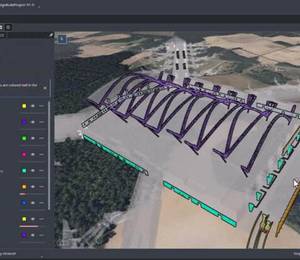

Three Terex Trucks TA400 articulated haulers are currently working on the Central Kowloon Route project in Hong Kong. Since last July, the machines have been in operation up to 20 hours daily, making close to 100 trips per day to clear out the debris from the 3.9 km tunnel construction.

The Government of Hong Kong has commissioned contractor Bouygues Travaux Publics – part of the Bouygues industrial group – to build the Central Kowloon Route, which will see an underground bypass constructed in response to the unsustainable traffic levels through central Hong Kong.

The TA400s play an important role in this infrastructure project. As the tunnelling machines are drilling and working their way forward into the rock, the Terex Trucks haulers are removing all the debris – up to 4,000 t each day. The material is then lifted to the surface through a shaft.

“We’re very happy with the performance of the Terex Trucks haulers,” said Christophe Jeanson, plant manager at Bouygues Travaux Publics. “We have a very tight schedule, so it’s great to know we can fully rely on the haulers to perform efficiently.”

“Terex Trucks’ TA400s are the natural choice for the demanding hauling work in the tunnel,” explained Gerald Lau, vice president sales and marketing of AP Rentals. “In Hong Kong, we see these haulers being used a lot for earth and vegetation clearance as well as transporting materials. They are robust and offer a very attractive total cost of ownership – that’s why Bouygues Travaux Publics selected the TA400s.”

Another reason was the big commitment from AP Rentals to support its customer. Since deploying the TA400s, the equipment rental company is in contact with the contractor every day, and during the daily visits on the jobsite the AP Rentals team ensures the Terex Trucks are ready to perform any time. If there’s ever any issue with the haulers, AP Rentals solves it on the spot.

Once the Central Kowloon Route is completed in 2024, the 4-km-long tunnel will consist of two tubes with three lanes each. It will link the Yau Ma Tei Interchange, West Kowloon, with the road network on Kai Tak Development and Kowloon Bay, East Kowloon, and is estimated to cut journey times for drivers down from half an hour to five minutes.

For operator comfort, the TA400 hauler is fitted with a spacious, ergonomically designed cab with pressurised properties. Acoustic insulation helps minimise noise levels inside the cab, while a high performance and easily adjusted heating, ventilation, and air conditioning (HVAC) system ensures a stable temperature.

The adaptive air suspension operator’s seat helps to deliver a comfortable work environment. The TA400 also boasts an adaptable six-stage transmission retarder as standard, which is supported by the hauler’s engine exhaust brake. This gives operators excellent control, without the need of applying any primary brake systems, and improves safety and stability while delivering a low cost of operation.

The TA400 has a heaped capacity of 23.3 cu m. Powered by a high performance, fuel-efficient engine that develops a gross power of 444 hp, the truck is designed to meet the demands of the most extreme operations such as large-scale construction projects, quarries and mines.

The machine’s planetary gear transmission provides smooth, efficient gear shifting for optimised fuel consumption and reduced cost of operation. Ground-level test points and a fully tilting cab, combined with an electronically raised hood, ensure ease of service and maximum uptime.

“Terex Trucks haulers are simple to operate and easy to maintain,” explained Lee Irving, regional business manager APAC and Oceania at Terex Trucks. “They are proven performer that deliver low total cost of ownership and high productivity.”

According to Terex Trucks, nine more TA400 articulated haulers are scheduled to be delivered to the project site later this year.