With an immense total length of 2,236 km, Vietnam’s National Route 1A is a heavily congested motorway along the section between kilometre 16 (Lang Son) and kilometre 170 (Hanoi). The road, which is narrow, steep and winding in some areas, is used by lorries, cars, countless motorbikes and even pedestrians.

To ensure its accessibility in the long run, the National Route 1A is being expanded for better performance and safety. Licogi 16 JSC – one of Vietnam’s largest construction companies with 20,000 employees – won the contract for an approximately 100-km section of the 154-km-long project.

Licogi 16’s civil engineering division is carrying out a number of road and bridge construction jobs on the project. To help with the work, the company opted for a track-mounted interlinked plant combination from Kleemann, a company of the Wirtgen Group. The machines were supplied by Vitrac, Wirtgen’s dealer in Vietnam.

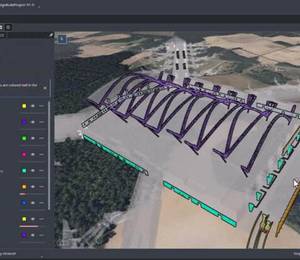

The interlinked plant combination comprises five units. Listed in the order of connection, they include an MC 110 Z Evo jaw crusher, an MCO 9 Evo cone crusher, an MS 703 Evo screening plant, an MCO 9 S Evo cone crusher and an MS 19 D screening plant.

In the quarry 40-km south of Lang Son, the Licogi 16 team found itself facing two challenges. Firstly, they needed to crush the hard and abrasive basalt and to classify it into clean aggregate fractions. Secondly, they had to fulfil very high-quality requirements.

Armed with the new Kleemann crushing and screening plants, the Licogi 16 team was able to meet the required criteria easily. The automated continuous feed system (CFS) played a key role in making the work easier.

The crushing plant in the first crushing stage – in this case, a Kleemann MC 110 Z Evo jaw crusher – only draws as much feed material into its crushing chamber as the entire line-coupled plant combination can process. This prevents overloads and, to the greatest possible extent, material blockages too.

Basalt is a vulcanite – an extremely hard and durable volcanic rock. The density of the hard rock comes to 3 t/cu m and is thus higher than that of granite, making it an excellent material for road construction. Kleemann’s mobile jaw crushing plants in the Mobicat series are particularly suitable for processing hard rock such as basalt in the first crushing stage, while those in the Mobicone series are ideal for the second crushing stage.