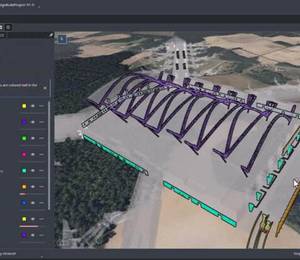

Sandvik’s new double-deck modular hanging screen, designed for its latest range of mobile 2-series crushers, enables customers to produce two screened products and recirculate any oversize back into the crusher. Among the benefits of this modular hanging screen is its ability to be adapted quickly for operation in open- or closed-circuit configurations.

With a modular design, the screen can be used as a fully self-contained, detachable or stand-alone unit. It is available on Sandvik QI442 Impactor, as well as Sandvik QH332 and QS332 cone crushers.

The screen is equipped with an adjustment system, which allows it to be quickly reconfigured to produce one single sized finished product or two sized finished products, depending upon the customer’s demands at that time. The screen can be hydraulically repositioned to create a single deck hanging screen, using the top deck as a breaker deck without the need for a screen mesh removal.

The oversize conveyor may be hydraulically rotated for material stockpiling (90°) of up to three products on the ground, or removal (180°). The tail section can also be raised hydraulically to give improved ground clearance for transport when loading or unloading.

The complete modular hanging screen can be installed or removed from the plant in less than 30 minutes, without the need for any lifting equipment on site. Sandvik’s hanging screen option delivers multi-functionality as a 1, 2 or 3-way split screener offering high flexibility to the customers.