The new Liebherr LRB 355.1 piling and drilling rig features an innovative design and intuitive assistance systems. According to the company, several units are already working on jobsites.

Available globally, the LRB 355.1 offers a multitude of application possibilities in deep foundation work, such as drilling with Kelly equipment or full displacement tools, and working with vibrators or hydraulic hammers.

For easy transportation, the rig’s crawlers can be removed from both types of undercarriage. This reduces the maximum transport weight by about 14 t. To minimise the transport length, the leader can be folded. For a longer leader version with 27 m, this saves 7 m. A further advantage is that the machine can be transported with a mounted leader, sledge and ropes. Thus, it can be mobilised even more quickly on the jobsite.

The LRB 355.1 is equipped with a 750 kW Liebherr diesel engine that complies with the NRMM exhaust certification Tier 4 and Stage V. The new BAT 450.1 with a torque of 450 kNm serves as rotary drive and has automatic torque regulation, continuous speed optimisation and four electronically adjustable speed ranges.

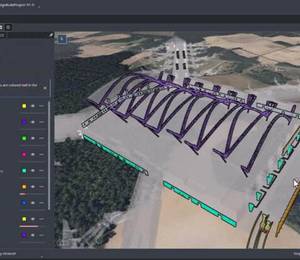

The ground pressure visualisation calculates the current ground pressure of the machine in real time and compares it with the specified safety limits of the relevant jobsite. This ground pressure is displayed in the operator's cab and the operator is continually aware of whether the machine is situated in, or is approaching, a critical area. Therefore, the operator can avoid dangerous movements.

Locking of the Kelly bar’s telescopic sections is made significantly easier with the aid of the Kelly visualisation system in the LRB 355.1. Thanks to the real-time display of the Kelly bar’s locking recesses on the cabin monitor, the operator always knows the actual distance to the next locking recess. Colour indications inform when the bar can be locked. Furthermore, false positioning of the Kelly bar during the shake-off process is indicated through a warning signal.

During continuous flight auger drilling, the concreting process is automated thanks to the drilling assistant. The remote control simplifies the loading process for transportation as well as the assembly of the machine. All assistance systems contribute to time savings, higher availability of the machine and a significant increase in safety during operation.

Another highlight of the LRB 355.1 is its new cabin, which focuses on operator comfort. It includes a modern air-conditioning system with improved airflow, an optimised field of vision and reduced noise emission, as well as an ergonomic operator’s seat with integrated heating and cooling.