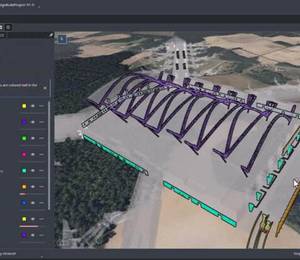

The Link-Belt SmartFly pinning system helps ensure proper fly erection and stowage sequence while minimising work at height. It is easy to erect and stow, thanks to its simple yet innovative design elements.

For rough terrain cranes, front carrier-mounted boom controls allow for raising and lowering the boom at ground level throughout the procedure. Colour-coded spring-loaded latches indicate which length fly is being erected or remaining stowed.

A hydraulic cylinder and ramp releases the fly and returns it to its stowed position. The interlocking access gates keep the fly secure at all times and guide the operator through the proper steps for pinning and unpinning the fly. Boom head speed screws provide fast, complete alignment and engagement of main connecting pins, all with the operator at ground level. All of this adds up to a logical design that is robust, simple and an efficient one-person operation.

The development of Link-Belt SmartFly began with its introduction on the HTC-86110 telescopic truck crane in 2015. The early success came from a collaboration between Link-Belt engineering and voice of the customer – developing a streamlined process for fly assembly that can be easily understood by operators, minimises work at height, and stands above countless industry methods. To date, Link-Belt has broadened SmartFly technology across multiple product lines – from on-highway truck cranes to telescopic crawler cranes, rough terrain cranes, and all-terrain cranes.