The reclamation work for Tuas Terminal Phase 2 recently began with the installation of the first caisson in a ceremony held on 4 July 2019. Once operational, it will add a capacity of 21 million twenty-foot equivalent unit (TEUs).

The Maritime and Port Authority of Singapore (MPA) will develop Tuas Next-Generation Port in four phases. MPA awarded the Tuas Terminal Phase 2 reclamation project to Penta-Ocean Construction Co Ltd/Hyundai Engineering & Construction Co Ltd/Boskalis International BV (PHB) Joint Venture in 2018.

MPA said this is the largest of the four phases to be reclaimed at 387 ha. The 8.6 km wharf structure will be constructed with 227 caissons that will be fabricated on site.

According to MPA, all container operations in Singapore will be consolidated at Tuas Terminal by the 2040s. When fully completed, the terminal will be able to handle up to 65 million TEUs annually.

“The installation of the first caisson for Phase 2 marks an important milestone in the development of the next-generation port at Tuas. Tuas Terminal will be digitalised and smart, and integrated with the wider supply chain network. This will be key to maintaining our position as a leading global hub port,” said Dr Lam Pin Min, Singapore’s Senior Minister of State for Transport and Health.

Modern construction methods, digitalised port process

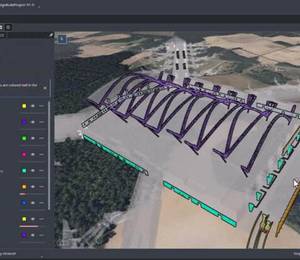

The Tuas Terminal Phase 2 project will use innovative, modern construction methods to boost safety and improve productivity, announced MPA. For example, it will apply a slip form jack monitoring system and rebar modularisation for the fabrication of the caissons.

The slip form jack monitoring system provides unobstructed view of the hydraulic system. This feature enhances the safety of workers through prompt rectifications of the hydraulic system. The process of rebar modularisation allows for the prefabrication of steel bars, which form part of the base slab. This significantly improves the safety of those working under the steel bars.

The project will also adopt modern construction technology such as an automated curing system, added MPA. An automated curing system refers to a water circulation system that helps to control the quality of the base slab.

The project will explore using artificial intelligence to monitor the construction site. For example, using facial recognition tools to detect security breaches at entry and exit points, and video analytics to detect unsafe acts and prevent potential injury at the caisson fabrication yard.

In addition, the Tuas Terminal will be highly digitalised to optimise processes and enhance information-flow and sharing. As a one-stop portal, MPA’s Maritime Single Window (MSW) will transform reporting and port clearance processes for ships calling at Singapore through data exchange amongst relevant stakeholders.

Phase 1 of the MSW is planned to be launched later this year, and will streamline processes of agencies such as MPA, National Environment Agency, and the Immigration and Checkpoints Authority.

Tuas Port will also be the first terminal in Singapore to be physically and digitally integrated with the wider supply chain network. CALISTATM, PSA’s supply chain platform developed by GeTS Asia Pte Ltd, is an example of a digital solution that will be integrated with the Tuas ecosystem. Such digital connectivity with key industry sectors in Tuas helps to improve efficiencies among stakeholders along the supply chain – vessels, cargo owners and logistics service providers – and better coordinate cargo flow in a secure and intelligent manner.