The Panglao Island International Airport - also known as New Bohol International Airport - is located on the Panglao Island in the Philippines province of Bohol. When completed, the airport will provide a capacity of up to two million passengers per year and it is also intended to replace the nearby Tagbilaran Airport.

The project is funded by the Japan International Cooperation Agency (JICA) under the New Bohol Airport Construction and Sustainable Environment Protection Project, which is owned by the Department of Transportation and Communications of the Republic of the Philippines.

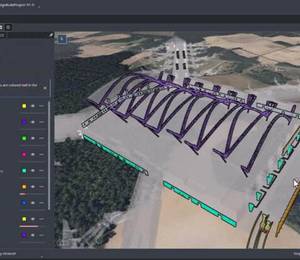

Construction work commenced in June 2015 and is expected to be completed by August 2018. The airport is being built on a 230-ha land and has a 2.5-km runway, which can be extended to 2.8 km in the future. The runway is designed to accommodate up to seven aircrafts at a time, including large international aircrafts.

Main contractor on the project, Chiyoda-Mitsubishi Joint Venture, subcontracted the civil portion of the project to provide the asphalt-treated base course, asphalt concrete surface and binder course for the runways and also for the access roads, perimeter roads, maintenance roads and carparks. Total area of asphalt works is approximately 350,000 sq m, requiring about 100,000 t of hot mix asphalt.

To help complete the job, the subcontractor chose two Linnhoff TSD1500 mobile asphalt plants, one of which was transferred from the previous project for the airport in Caticlan. This asphalt plant model is considered a suitable option for similar short-term projects due to its full mobility features. The TSD1500 is easy to assemble and disassemble, making it convenient for jobsite transport. It delivers an average capacity of 80-100 t/hr at 5% moisture.

The basic Linnhoff mobile asphalt plant unit consists of four modules with built-in axles. These mobile modules are designed to conform to international road haulage standards for faster and easier mobility. As such, the use of Linnhoff TSD1500 in this project allows the distance between the plant and the jobsite, as well as the land area for plant installation, to be reduced. The close proximity of the plant to the jobsite is important in order to meet the strict requirement of the temperature for the hot mix asphalt.

According to the subcontractor, Linnhoff asphalt mixing plants provide less air, less noise pollution and less maintenance cost. The Linnhoff screen drum technology combines the drying and screening of aggregates in one drum, so there is no need for a hot elevator or vibrating screens. Due to this, maintenance on Linnhoff asphalt plants can be lower compared to other asphalt plants because they do not require chains, extra motor or buckets. Furthermore, Linnhoff asphalt plants provide accurate weighing of mineral aggregates, bitumen and filler by load cells, resulting in good quality homogeneous hot mix asphalt.

Website: www.lintec-linnhoff.com